HTS Texas, the Texas partner of the largest independent commercial HVAC manufacturers’ representatives in North America, announced today it supplied the 345,000 sq. ft. Lakeway Regional Medical Center with an energy-efficient central plant and dehumidification system that resulted in $165,000 of energy rebates for the facility.

“Medical facilities have unique needs requiring custom heating and cooling products,” said David Driggers, system sales representative for HTS Texas. “We are committed to helping owners, engineers and contractors achieve real success through the availability of HTS Texas’ energy-efficient HVAC solutions that ensure patient and tenant comfort.”

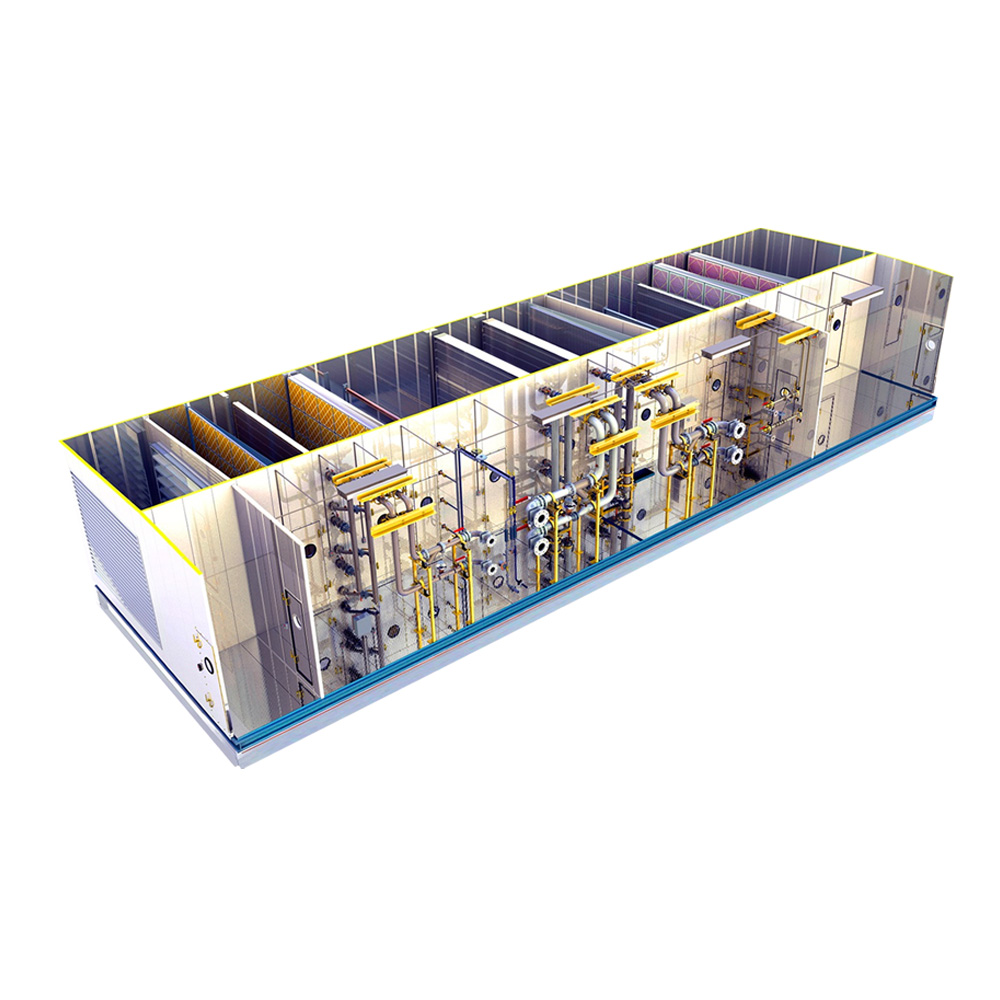

Page Southerland Page, a full-service architecture and engineering design firm, selected HTS Texas to help Lakeway Regional Medical Center reach its specific design requirements for the building:

• a custom central plant that pulls heat from the condenser water system for use in the templifier to generate reheat for the hospital and eliminate need for a propane boiler that requires natural gas;

• a dehumidification system that properly regulates air temperatures for the hospital operating rooms and labor/delivery suites; and

• the option to run equipment on temporary power.

“A successful medical construction project is characterized by maintaining the bottom line without sacrificing efficiency and patient comfort,” said Randy Twedt, senior associate for PageSoutherlandPage. “HTS Texas provided the most comprehensive plan to help reach the project’s goals.”

To help Lakeway Regional Medical Center reach its pending LEED (Leadership in Energy and Environmental Design) Gold status and secure $165,000 in rebates from Austin Energy, the nation’s eighth largest community-owned electric utility, HTS Texas worked with Dynamic Systems, to install:

• three 600 ton Daikin Applied WSC100 Centrifugals with VFDs;

• two 350 ton Daikin Applied TSC063 Centrifugal Templifiers with VFDs;

• five Daikin Applied Vision Air Units;

• two Haakon Airpaks with SEMCO wheels and Armstrong humidifiers;

• one Haakon Airpak;

• nine blower coil units; and

• twelve Armstrong EUH Electric Humidifiers.

“The project goals were very specific and it was a pleasure to partner with HTS Texas to exceed desired outcomes and provide ongoing cost-savings for the customer,” said Ryan Rehmann, project manager for Dynamic Systems, a leading provider of fabrication and installation of high purity piping systems, process exhaust, HVAC piping/sheet metal and sanitary plumbing.