HTS Texas provided a unique, energy-efficient HVAC system at the new H-E-B at Mueller, a state-of-the-art 83,000 square-foot food and general merchandise market in Austin, TX.

The new H-E-B was designed as a test store for innovations in environmental sustainability and is the greenest H-E-B store to date. Cutting-edge design and equipment used will contribute to industry-leading reductions in energy use, potable water use, and recycling.

HTS Texas was chosen for this project for its exceptional expertise in sustainable HVAC design solutions and provided guidance for installing H-E-B’s first chilled water system. The chilled water also feeds the refrigeration system and the rejected heat is used for radiant heating and cooling of the floors, which contributes to the store’s sustainability efforts.

“To meet the challenge of making the Mueller store the greenest H-E-B to date, HTS Texas and Daikin Applied provided a customized chilled water system that is significantly more energy-efficient compared to industry-standard while offering a comfortable climate for the store patrons,” said Paul Naizer, HTS Texas Branch Manager. “We also provided the necessary guidance for proper application and sequencing to maximize the system’s functionality.”

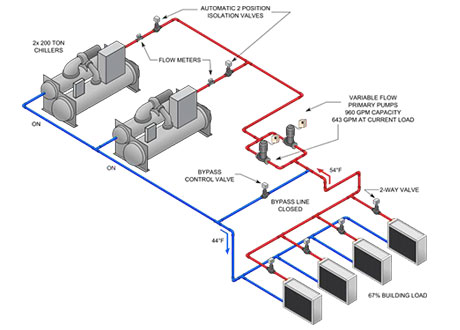

The 500-ton Daikin Modular Central Plant (MCP), a pre-engineered, pre-assembled module, combined two 250-ton Daikin Magnitude® Chillers, a boiler, a cooling tower, and pumps. The MCP is conditioned with Daikin chilled water fan coils and unit heaters.

The assembly also included the Building Automation System (BAS), with Siemens and HTS controls, an Alfa Laval plate, and frame heat exchangers for tempered chilled and hot water loops. Additional equipment included Daikin RDS rooftop units, IEC fan coil units, Griswold piping packages, and ancillary equipment from HTS Controls was used to connect outdoor units to the MCP system.