The emergence of antibiotic-resistant superbugs, the rising frequency of Hospital Acquired Infections, and the continued presence of highly infectious diseases (AIDS, TB), has raised infection control to the top of the list of difficult issues facing health care facilities today. In order to continue to provide safe healing environments, hospitals must continually implement measures to maintain all patient-occupied areas as contaminant-free as possible.

Infection-preventing clinical measures (sterile gloves and gowns, wound sterilization, etc) are important standard procedures. Measures for control of airborne contaminants are less well known but of equal importance, particularly in the event of an airborne pandemic – a widespread outbreak of infectious disease. In these cases, the isolation of all infected patients from the healthy population can mean the difference between remote instances of illness and a full-blown epidemic.

While planning the construction of its new nine-story patient tower in 2007, Northwest Community Hospital in Arlington Heights, IL, wished to address the infection isolation issue upfront, by incorporating into the building design a system that maintained accurate and stable space pressure and directional airflow in designated patient spaces. The project architect, OWP&P, turned to critical airflow experts HTS Chicago for assistance.

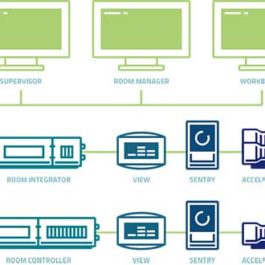

The HTS Chicago team designed and supplied a complete Phoenix Controls System consisting of 269 Phoenix Venturi air valves with pandemic ready controls. With this system in place, the hospital can supply positive or negative pressure to not only individual patient rooms, but also to the entire fifth and/or ninth floors of the tower, thereby creating pandemic isolation areas capable of safely harboring large numbers of infected patients. All of this can be accomplished on-demand by issuing a single building management system (BMS) command to the Phoenix Controls System.