The CISSS de l’Outaouais has initiated a project at the Hull Hospital to enhance HVAC systems to meet stringent air quality standards, maximize energy efficiency, and ensure robust construction for its operating rooms.

Recognizing the necessity for a fully redundant and custom solution, the hospital selected Haakon AHUs. These units feature an energy recovery wheel that recovers energy from the exhaust airstream and pre-conditions the fresh air stream. This process improves energy efficiency and ensures superior air quality in the operating rooms.

To further enhance energy efficiency, the hospital chose the Aermec NRB chiller. This chiller is capable of operating in heat pump mode, which allows for significant energy recovery during shoulder seasons. By utilizing heat pump technology, the chiller reduces the reliance on steam produced by gas boilers, thereby lowering overall energy consumption and carbon footprint.

By integrating these advanced HVAC solutions, the Hull Hospital ensures superior air quality, enhanced energy efficiency, and reliable performance in its operating rooms. These improvements underscore the hospital’s commitment to providing the highest standards of patient care through state-of-the-art technology and sustainable practices.

HTS supplied the following equipment:

- Haakon AHU with Heat Recovery

- Aermec NRB Chiller

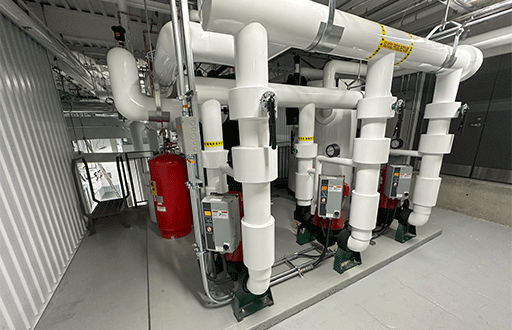

- Bell & Gossett Pumps, Expansion Tanks & Air Separator

- DriSteem Reverse Osmosis Skid Package

- DriSteem GTS LX Humidifiers

- Sigma Unit Heaters

- Kinetics Spring Isolators